our projects

The team at Curtis were integral to the magnificent refurbishment of The Queens Hotel in Leeds. All the bedrooms were transformed plus 17 new added, bringing the room total to 232 including a Presidential Suite. Curtis’s designers helped to achieve the art-deco inspired interiors. Choosing Curtis offered huge advantages from the initial consultations and site visits, right though to delivery and installation."

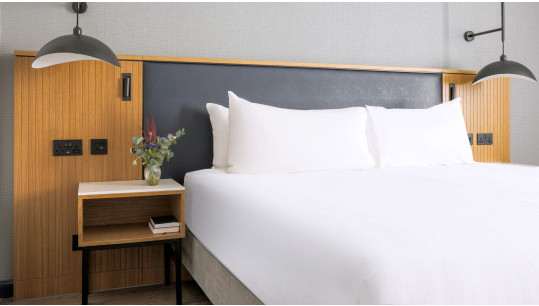

In developing our design and aesthetic for our first Residents Club in South Kensington, it was essential to find exactly the right furniture partner. We wanted a company that would be completely in tune with our ambitions and yet contribute their own specialist knowledge - and in line with our commitment to sustainability, it was a key priority they should be a UK based manufacturer. The partnership we formed with Curtis delivered on all these key requirements and we look forward to working with Curtis again."

The hotel's floor footprint resulted in various room types and configurations to accommodate the available space. To ensure the correct setup and components for each room, a master matrix was developed for Curtis to refer to. Each phase had a one-month timeframe, which Curtis had to manage efficiently to meet handover deadlines. Occasionally, the team had to work at a fast pace to accommodate additional joinery requested by the client. But the installation process was consistent throughout each phase to meet handover.

Curtis manufactured 312 rooms of high quality, bespoke bedroom furniture for The Tribe hotel. Communication was speedy and consistent, and the furniture received was of high quality and offered excellent value for money. Due to the scale of the project there were changes and issues which Curtis helped us to overcome. I look forward to working with Curtis on further projects in the future.

“Much of a Hotel Indigo’s retelling of their individual neighbourhood story is achieved through design, weaving in local themes and references, thus demanding bespoke, considered solutions rather than standard off-the-peg options. Curtis’ genuine interest in the successful execution of the brief, giving nods to the local goldsmiths, architects and horologists, was both reassuringly productive and also refreshing. The initial expectations from us, the client, did not encompass the flexibility, time and grace that the Curtis team utilised, allowing the successful navigation around the preliminary value engineering and design adaptation demands, nor did we predict the continuation of this additional layer of client support which transpired to be pivotal to dissolving several unexpected hurdles which emerged as the build progressed.”

"We partnered with Curtis for the refurbishment of 34 executive rooms and suites as part of the first phase of our upgrade at Vale Resort, and the experience was good from start to finish.

Working directly with their team, we found Curtis to be professional, responsive and highly collaborative throughout the process. The furniture was manufactured and installed to a high standard, with great attention to detail. The finished rooms have elevated the look and feel of our executive offering, delivering the quality and comfort our guests expect. We would be happy to recommend the team at Curtis.”

County worked with Curtis on the recent renovation of 301 bedrooms at the Delta by Marriott in Bristol city centre. The renovation took place over 10 phases whilst the hotel was in operation. From start to finish this refurbishment project was managed by our project management team and the Curtis dedicated project management team who went above and beyond to ensure the project ran smoothly and to schedule. We have worked with Curtis on many projects and will continue to do so in future."

We have worked with the team at Curtis for over 20 years and on various hotel brands and private owners. They respond promptly when design information is issued and provide detailed quotations. They are also proactive when helping to resolve budgets or programme issues which arise. Their UK factory enables them to provide high quality furniture and to be flexible in meeting the challenges of large and complex installations."

Having partnered with Curtis Furniture on previous projects in the UK, we were pleased to appoint them as the bedroom furnishings supplier for Seaton House and Dunluce Lodge. Their meticulous attention to detail throughout the planning and manufacturing processes was greatly appreciated. They executed the design vision of each property flawlessly, while ensuring each remained distinctive.